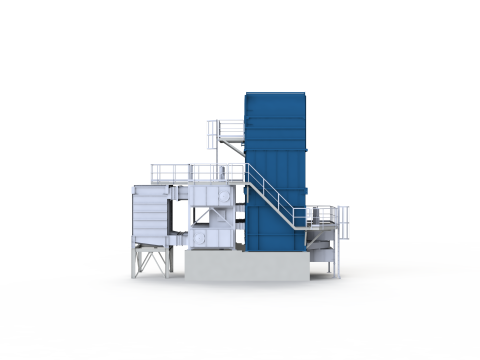

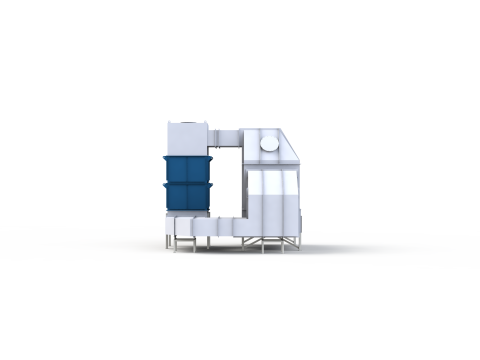

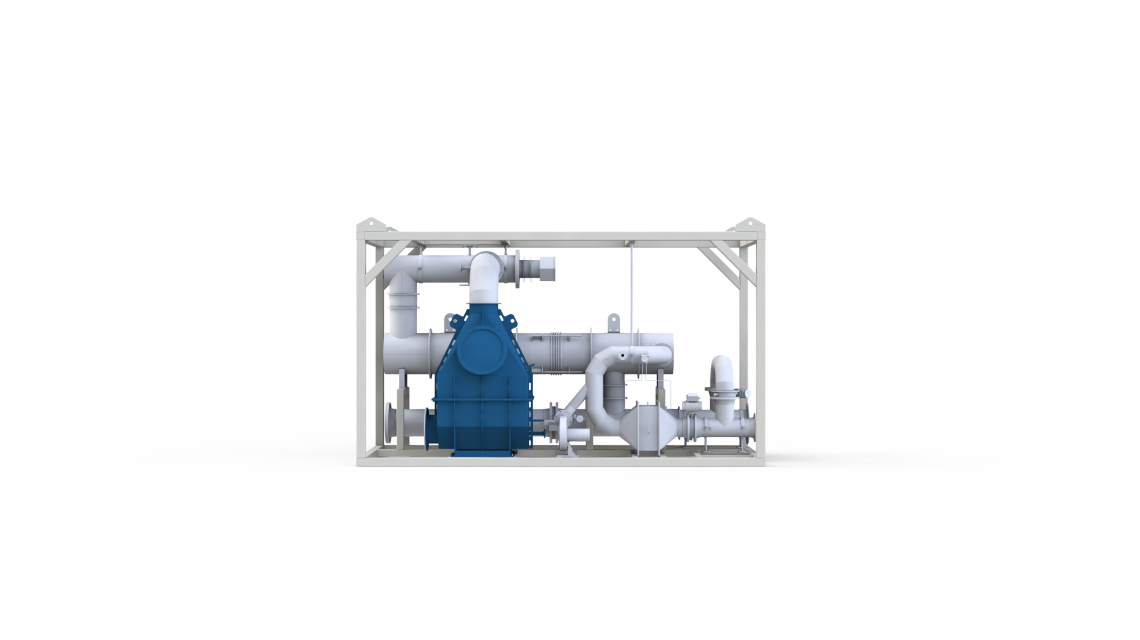

RecuKAT

Recuperative CO

- Maximum cleaning efficiency

- CTP’s own high performance, custom-made "nobel-metal" and "metal-oxide" oxidation catalyst

- Constant high performance – also for oxygen-poor gases

For high cleaning efficiency, the RecuKAT's attractive economic performance is due to the low reaction temperature of the CTP catalysts.

CTP can refer to 40 years of experience with catalysts in industrial applications. The RecuKAT is suitable for small to medium gas flows with low or high concentrations.

Features:

- Maximum cleaning efficiency

- CTP’s high performance bulk catalysts treating:

- a wide variety of hydrocarbons (e.g. alkanes (>C4), olefins, aromatics, alcohols, aldehydes, ketones, organic acids)

- methane and short-chain alkanes (C1-C4)

- halogenated hydrocarbons, nitrogen containing hydrocarbons

- carbon monoxide

- ammonia

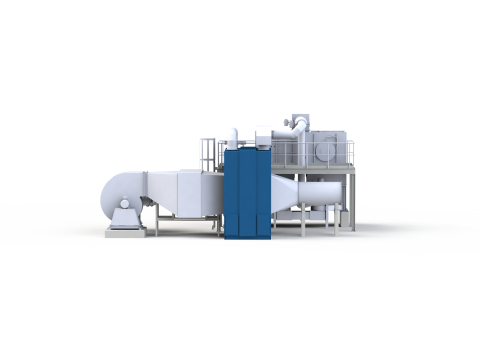

- Effective shell tube heat exchanger (>75%)

- Cleaning of gases with low oxygen content (residual oxygen content <0.2% vol.)

- High availability

- Weatherproof installation of instrumentation and heating system

- Field proven advanced software

- No NOx is formed when oxidizing ammonia (NH3)

- Cleaning of oxygen-poor gases

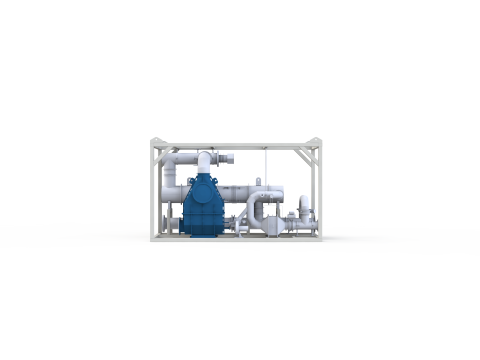

- Available for low and high pressure processes up to >25 bar

- CO2 polishing

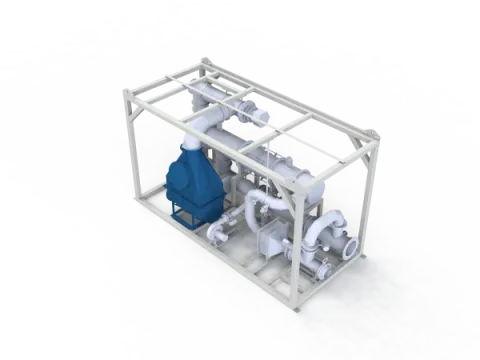

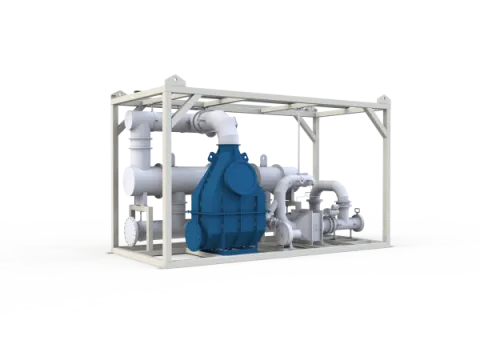

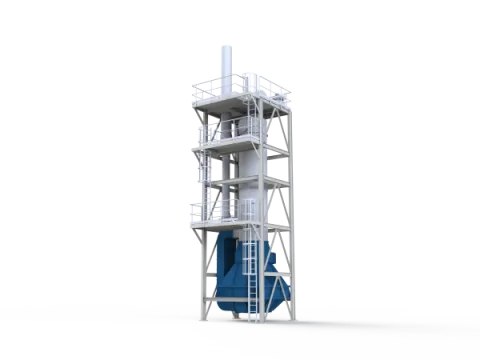

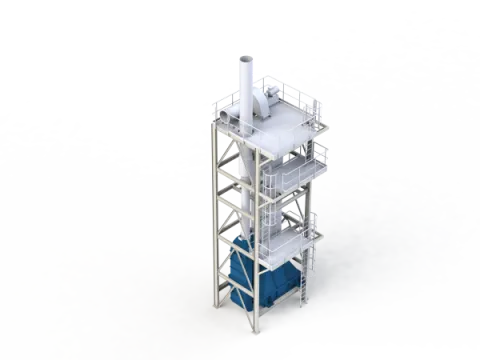

- Horizontal and vertical configuration

- Small footprint

Available options:

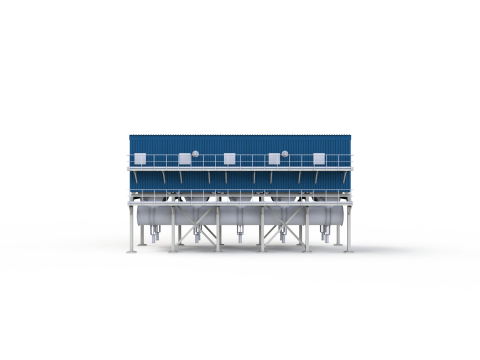

- Selective pre-separation of sulfur compounds

- Coarse and deep desulfurisation

- Combination oxidation-catalyst and DeNOx or N2O catalyst resp. dioxin catalyst

- Combination with scrubber for SOx or HCl, HBr

- Electric heating or gas burner

- Hot bypass

- Heat recovery

- Multi-layer catalyst

- Horizontal or vertical configuration available

- LEL safeguard

- Residual oxygen content control

- External energy recovery

Realize your ideas using our products

Are you interested in our products and services?

Do you need more information?

Send us your question or request a call. We are here for you!