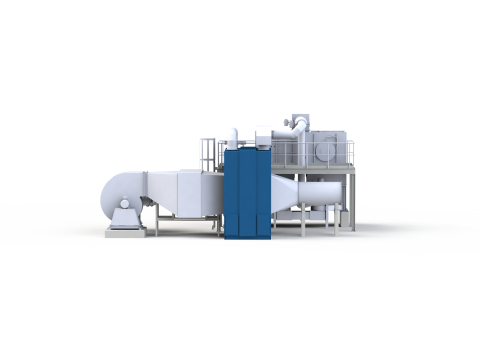

MultiTherm

TO

- Maximum destruction efficiency

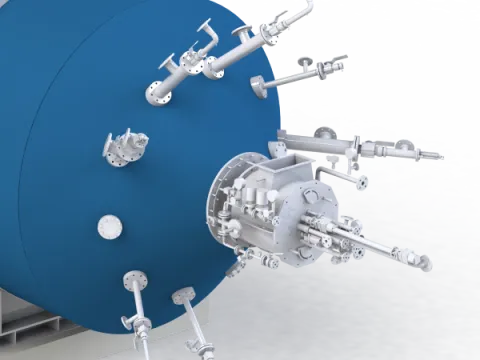

- Special burners (e.g. oxygen, LowNOx, solvents, tar)

- Specially designed CTP nozzle for fuel injection

- Universal applicability

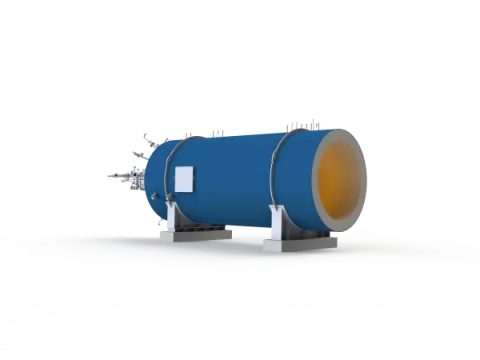

For safe removal of highly contaminated, i.e. halogenous, waste gas streams and liquid waste as well as wastewaters, especially in the pharmaceutical, chemical and petrochemical industry.

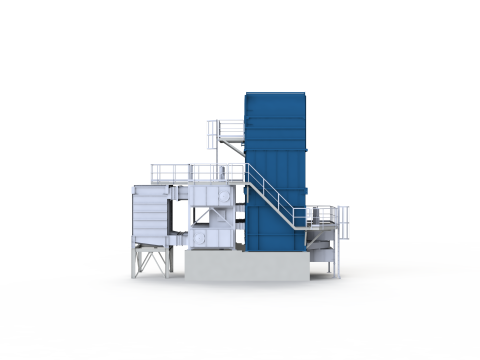

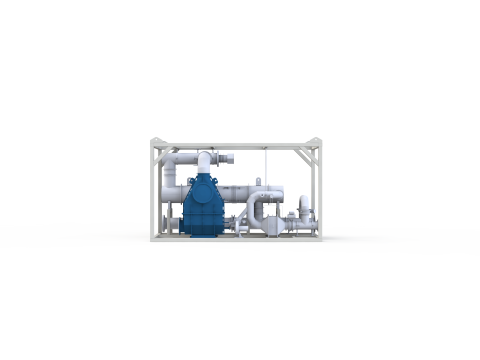

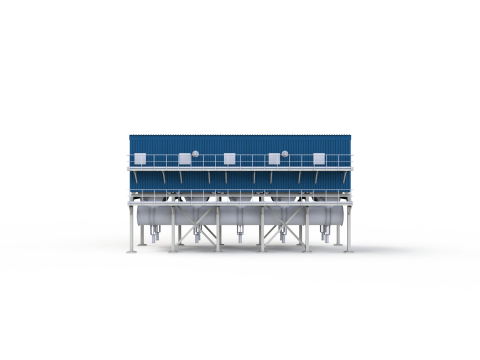

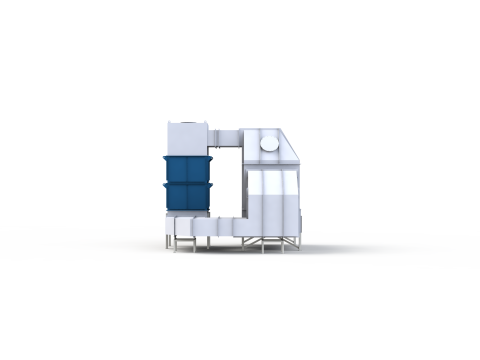

CTP‘s MultiTherm is a combined process. It consists essentially of a thermal oxidation and one or more upstream or downstream processes fitted to the application. These could be heat recovery, wet scrubbing and DeNOx, among others. Our burner system has managed the simultaneous combustion of many highly variable waste streams.

Features:

- Maximum destruction efficiency

- Efficient multifuel burners

- Modular design

- Uniform flame shape

- Turbulent flue gas recirculation

- Optimized fuel injection

- Optimized fuel distribution

- Variable injection lances

- Ultrasonic nozzles

- Flashback free operation

- High saftey standard

- Fail-safe PLC

- Selected sensors with SIL classification

- High availability

- Adaptive control software for changing load conditions

- Control concept optimized in operating costs

- Flexible combustion chamber design

Available options:

- Safety technology (static dry or wet flame arrestors, dynamic flash-back protection)

- Low heat-loss combustion chamber (multilayer insulation and recovey of heat-loss)

- Selective Catalytic Reduction (SCR)

- Selective Non-Catalytic Reduction (SNCR)

- Heat recovery

- Quench/Scrubber

- Residual oxygen control

Realize your ideas using our products

Are you interested in our products and services?

Do you need more information?

Send us your question or request a call. We are here for you!