The world's appetite for electronic devices - from simple household appliances to sophisticated computers - has led to rapid growth of both these industries.

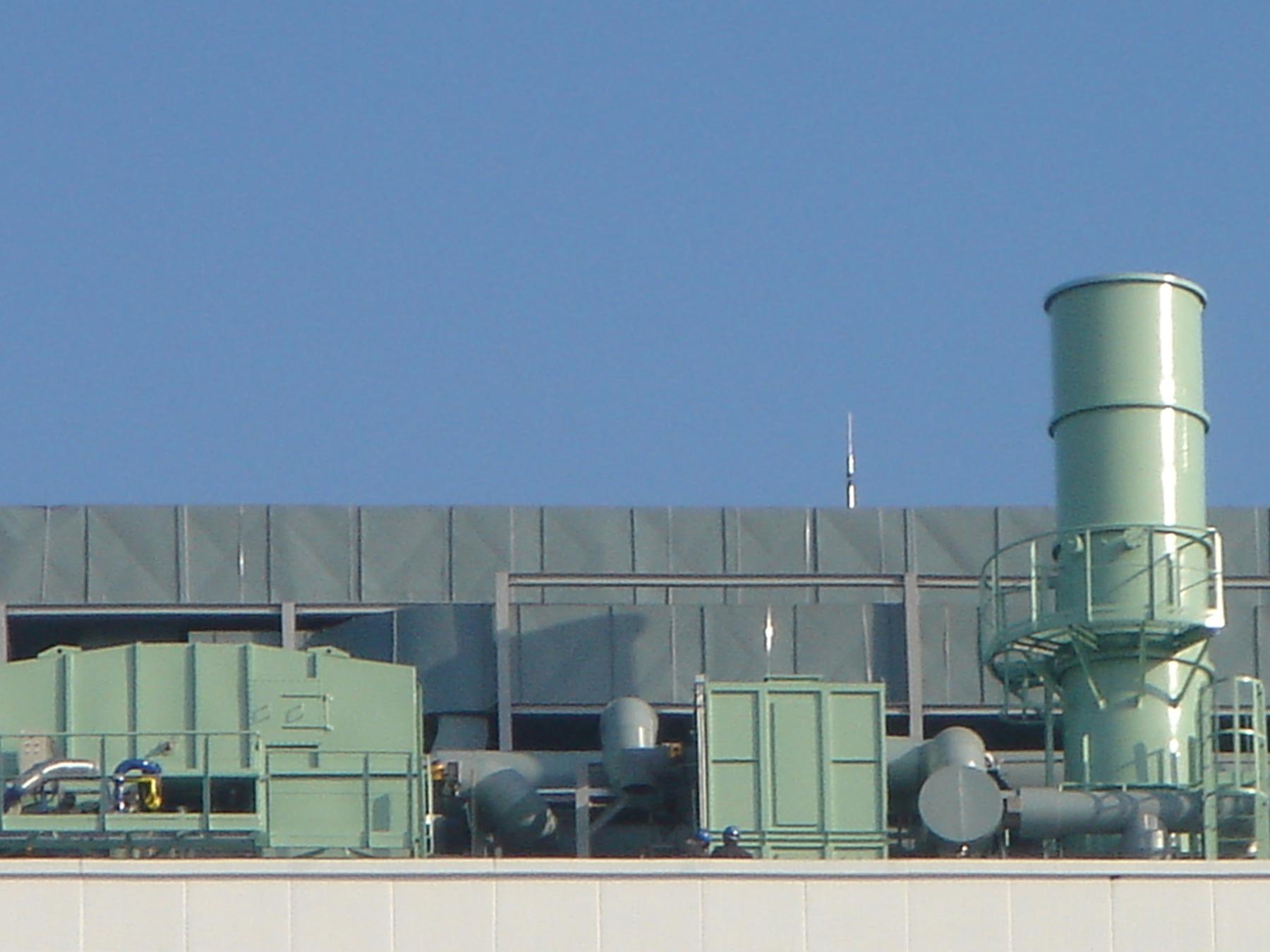

Typically for the electronics industry are large waste gas streams (up to 400.000 Nm³/h) with relatively low concentrations of different solvents. The electronics industry has important standards to meet regarding environmental protection. CTP complies with these requirements: From zero emission goals, to installations on the roofs of production facilities.

The electrical industry produces waste gases from dryers, kilns, and coating machines that occur in the production of basic elements such as motherboards, or end products such as motors or neon tubes. CTP has developed interesting applications and solutions in air pollution control in this industry.

Did you know?

In 1989 CTP supplied the first honeycomb RTO (AutoTherm) worldwide! This RTO for a customer in the electrical industry is still in operation.

Realize your ideas using our products

Are you interested in our products and services?

Do you need more information?

Send us your question or request a call. We are here for you!

Some selected example references

TFT LCD OLED

Emission source:

Stripper processes

Contaminants:

Volatile organic compounds

CTP system:

RotorSorb (3 x rotary concentrators) and oil mist filter for 165.000 Nm³/h

Wires for transformers

Emission source:

Painting machines

Contaminants:

- Organic C

- Dust

- Carbon monoxide

- Nitrogen oxides (NOx)

CTP system:

2-bed RTO incl. heat recovery for 18.000 Nm³/h

Insulation material for electronic products

Emission source:

Mica tape drying and impregnation

Contaminants:

Volatile organic compounds

CTP system:

AutoTherm incl. heat recovery for 40.000 Nm³/h

Semiconductor

Emission source:

Cleaning and etching process of wafers

Contaminants:

Volatile organic compounds

CTP system:

RotorSorb (2 x rotary concentrators) for 92.000 Nm³/h